1.General Application

Development and design with the optical digital technology.

It's mainly applied to the safety valve test bench, valve test bench and other valve leakage test, as well as laboratory scientific research.

In compliance with the Standard API-527.

Overall modular design, high accuracy, simple design and convenient operation.

2.Technical Parameters

1) Test medium: Gas

2) Work pressure: Max.8 bar

3) Power supply: AC220V,50Hz

4) Sampling frequency: Max.3 nos/sec.

5) Sampling accuracy: ±1%

6) Counting range: 99999

7) Communication function: RS485

8) Time range:99.99 sec.;99.99 min.;99.99 hrs.

9) Time mode: positive timing or countdown

10)Environment: indoor working condition

3. Production Introduction

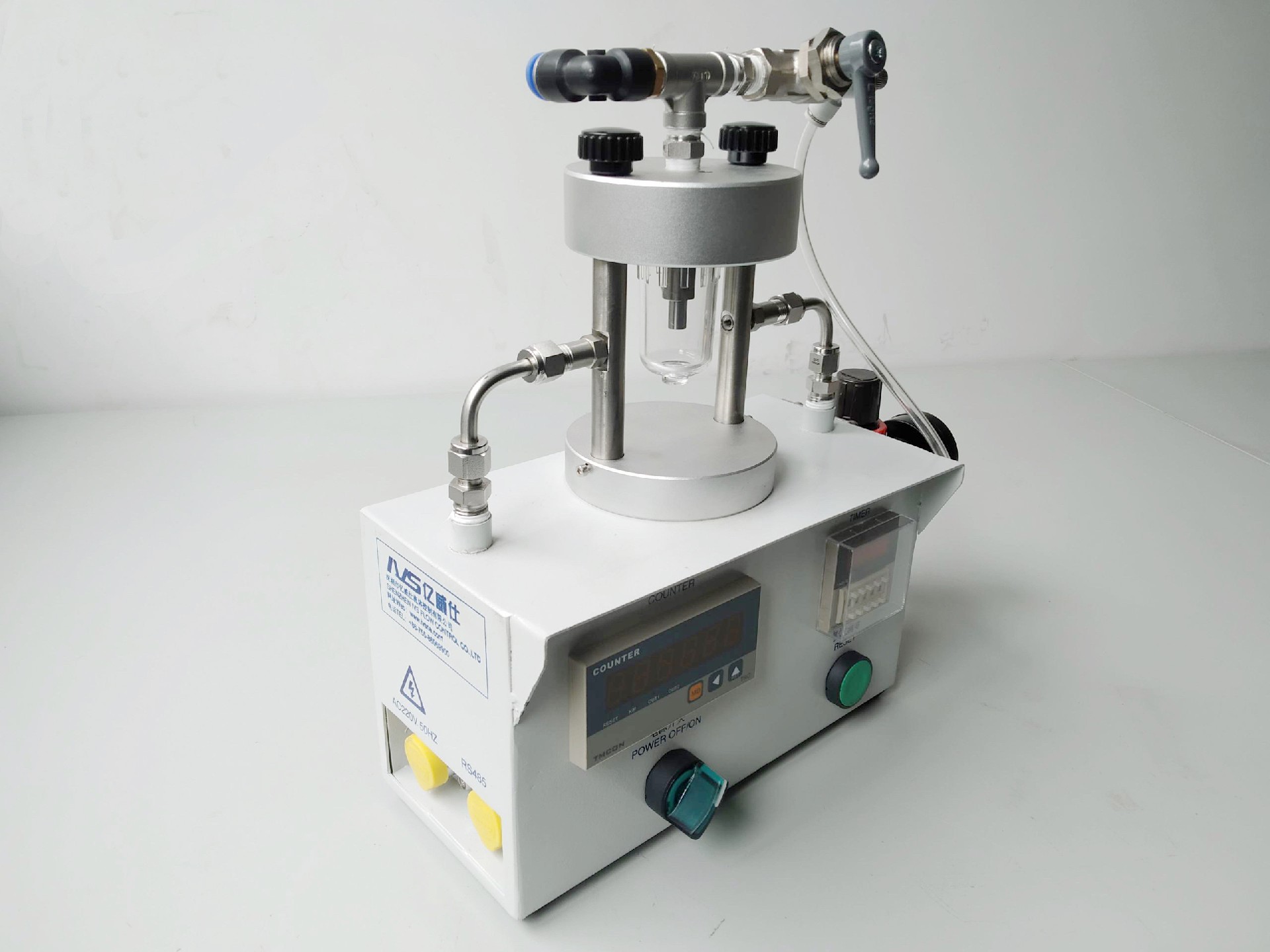

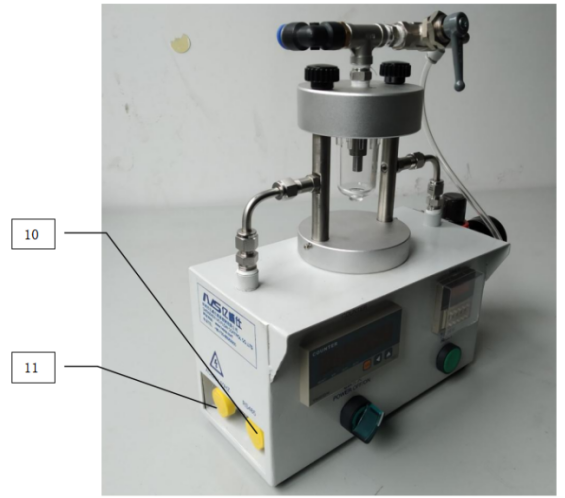

| NO. | Type | Description | |

1 | Gas leakage port | Connect to tested specimen outlet port with 8mm air hose | ||

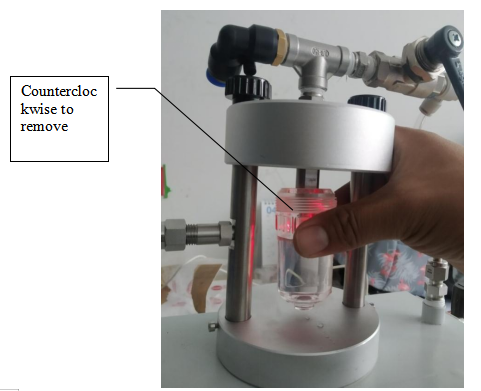

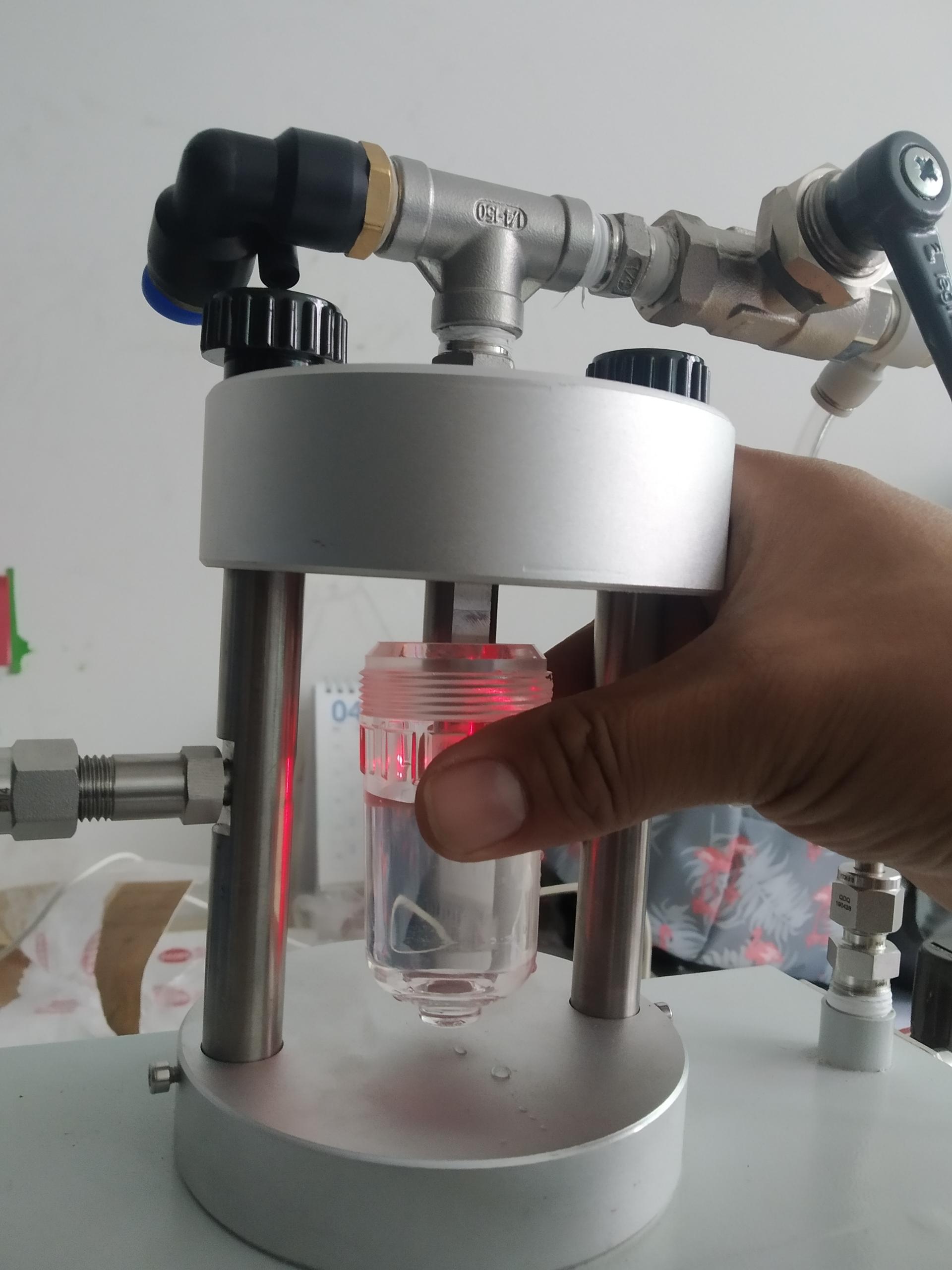

2 | Bubble Viewer | Visible cup for the bubbles with water inside | ||

3 | Counter | Record the bubble quantity | ||

4 | Power Switch | Turn right for on,turn left for off | ||

5 | Ball Valve | The switch for Air supply | ||

6 | Throttle Valve | Calibration and adjustment of bubble speed | ||

7 | Regulating Valve | Calibration and adjustment of air supply pressure with 10mmair hose | ||

8 | Timer | To set the time for recording bubbles | ||

9 | Timing start or reset | To delete the data and reset for timing | ||

| 10 | Communication port | RS485 (provided 3 m line with vendor) | |

11 | Power port | AC220V (provided 3 m line with vendor) | ||

4. Operation Procedures

1) Add water to the water cup: the liquid level shall be over the small diameter (i.e. the depth of the liquid level is 12.5mm)

2) Connect power: Power on

3) Connect 485 communication: if necessary

4) Connect the specimen

5) Connect the calibration air source: adjust the pressure to 1Bar, adjust the throttle valve to slowly and continuously discharge the bubbles.

6) Functions of the calibration gas:

A) To calibrate whether the counter is accurated.

B) To prefill the tested pipeline and valve with gas.

C) To verify whether there is leakage in the tested pipeline and valve.

7) After above process are completed, then start the counting:

A) To Set the time

B) Push to reset

C) Start timing and start counting

D) Time to the end of the counting

E) Keep displaying the current quantity

8) Operation completion

9) Operation for changing water and adding water of the cup