| Application: IVS Impulse test stand is applied to performing the impulse/fatigue/life time test on automobile steering hoses, brake hoses, air-conditioner hoses, fuel pipes, cooling water pipes, radiator hoses, heater hoses, air filter hosse, turbo, Booster system hoses, engineering hydraulic hoses, aerospace hose & hose assemblies, other pipes or end fittings , heat exchanger , air conditioner, filters, etc Technical data: · Max impulse pressure: 70Mpa (Accuracy: 0.1Mpa)

· Test waveform: Basic Square Waveform, T Waveform, Triangle Waveform, Sine Waveform *(Optional)

· Frequency: 0~1.5Hz (Depends on the total volume & physical character.

· Ambient temperature: Normal Temp or -40~150±3℃

· Medium temperature: Normal Temp~150±3℃ or -40~150±3℃

· Test pieces: 2-8 pcs (Depends on the total volume & physical character.

· Test medium: Hydraulic oil or DOT

· Pulsing cycles: >10 million cycles

· Test waveform: Basic Square Waveform, T Waveform, Triangle Waveform, Sine Waveform *(Optional)Mounting mode: 1800 or 900 (As per the standard)

· Dimension:3modules:

· PC console: customized size

· Power station: 1800mm×1200mm×1600mm

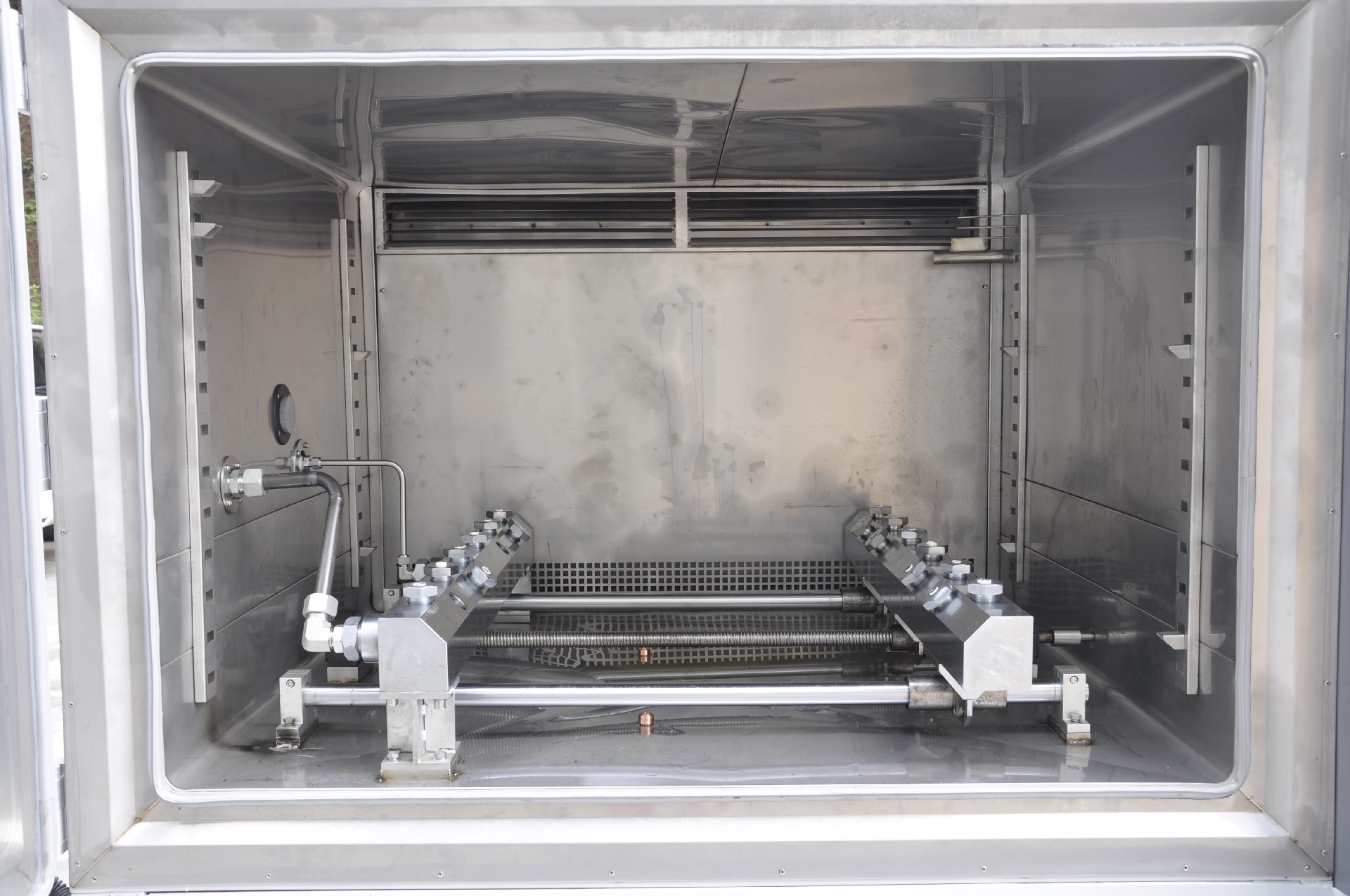

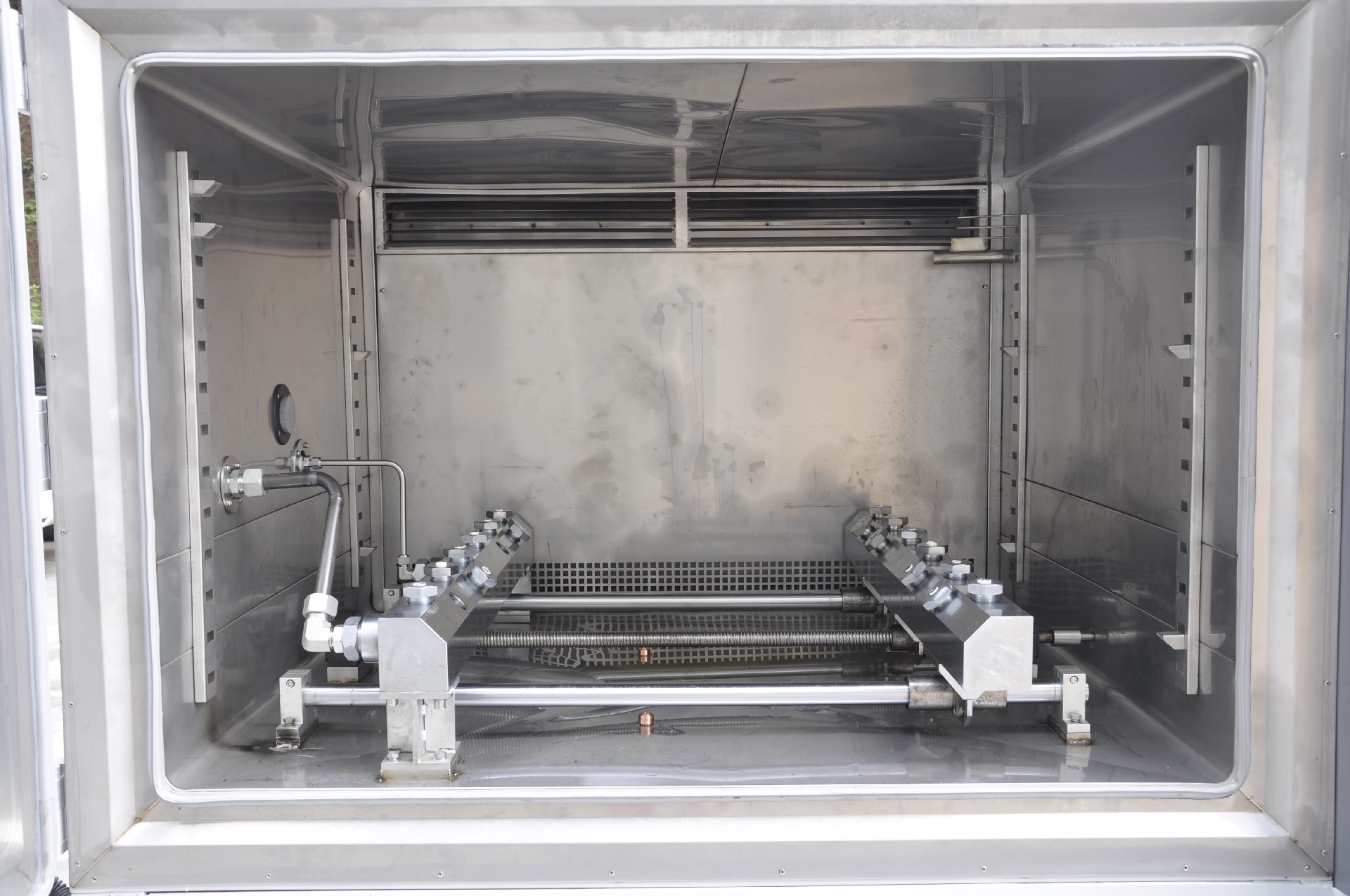

· Test Chamber:1500mm×900mm×1000mm Features: · Fully automated test stand with high speed data acquisition system.

· History screen and real-time display of pressure-time curves.

· Test data saved automatically when emergency or power down happens accidentally.

· Multi-samples can be tested independently at a time.

· From the control theory to the quality, advanced electrical components guarantee high test precision and stability.

· IVS test software is programmable, stable and reliable.

· Automatic pressure maintaining reduced the working time of motor and pressurizing section, enhanced the stability, life time and pressure precision of whole testing system.

· Equipment features overpressure/overload protection.

· Auto stop testing when a rupture occurs, prevent the operators and equipment from damages to the utmost.

· Automatically drain the air off remained in the test specimen at the beginning of the test.

· Providing with various of fixtures to satisfy the connecting of hose and hose assemblies.

· Installing distance adjustable freely as per hoses'minimum bend radius and test standards.

· Impulse test with flexing or without flexing. *(Optional) |  |